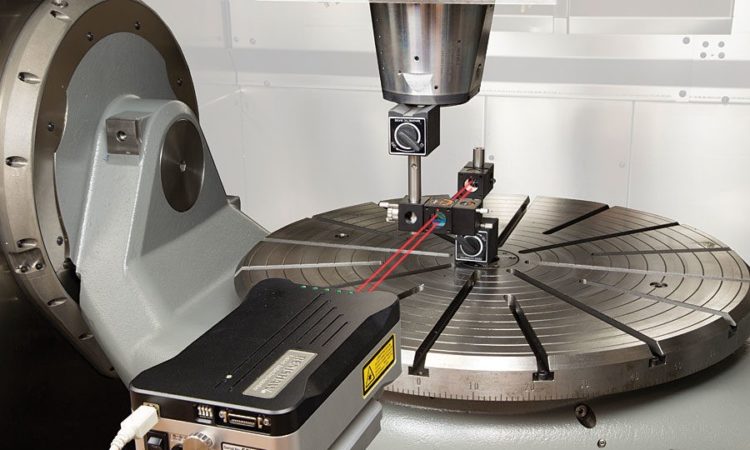

If you’re not familiar with CNC calibration, you might be wondering what it is and why you need it. CNC calibration is the process of ensuring that your computer numerical control machine is running accurately and precisely. In other words, it ensures that your machine is cutting or shaping material exactly as it should be. There are a few different ways to calibrate a CNC machine, but the most common is by using a probe. This probe is attached to the machine and used to take measurements of the material being cut. The probe’s readings are then compared to the machine’s actual output to make sure everything is accurate. Calibrating your cnc machining appleton wi is important for a number of reasons. First, it can help improve the quality of your finished products. If your machine is not running accurately, the chances of errors or defects in your finished products increase. Second, accurate CNC machining can help save time and money by reducing waste material and scrap. Finally, regular calibration can help extend the lifespan of your CNC machine by keeping it running smoothly and preventing wear and tear.

What are CNC Calibration Services?

CNC calibration services are a type of machine maintenance that is performed to keep your CNC machines running smoothly and accurately. The calibration process ensures that the machines are able to produce parts that meet your specific tolerances. These services can be performed by an outside company or in-house by trained personnel. There are many benefits to having CNC calibration company performed on your machines. First, it can save you money in the long run by prolonging the life of your CNC machines. Second, it can improve the quality of your products by ensuring that they meet your precise specifications. Third, it can increase productivity by reducing downtime due to machine malfunctions. Although CNC calibration services can be beneficial, they are not always necessary. You should consider having them performed if you notice any decrease in the quality of your products or if your machines are not running as smoothly as they used to. These services can be expensive, so be sure to weigh the cost against the benefits before making a decision.

The Benefits of CNC Calibration Services

If you’re looking for a way to improve the accuracy of your CNC machine, you may want to consider investing in CNC calibration company services. Here’s a look at what these services can do for you and why they may be worth the investment: One of the main benefits of CNC calibration services is that they can help improve the accuracy of your machine. This is because the technicians performing the calibration will make sure that all of the machine’s components are properly aligned and working correctly. As a result, you can expect your machine to produce more accurate results. Another benefit of CNC calibration is that it can help reduce your scrap rate. In other words, if your machine is producing inaccurate results, it’s likely that you’ll end up scrapping more material than necessary. By having your machine calibrated on a regular basis, you can avoid this waste and keep your costs down. Investing in CNC calibration services can also help you avoid downtime. If your machine isn’t operating accurately, it’s likely that it will break down more often, which can lead to costly downtime for your business. By keeping your machine well-maintained with calibrations, you can minimize the risk of unexpected downtime and keep your production running smoothly.